Shun Ji Wei has obtained the IATF-16949 Automotive Quality Management System Certification and enjoys a reputation of high quality and high reliability in the industry. The quality assurance department at Shun Ji Wei focuses on fulfilling the customer's quality requirements through sustainable management, consistency, rigorous examination, and zero defect manufacturing.

Quality Control System Perfect quality control system (TQM) from incoming materials, semi-finished products, finished products, assembly, inspection procedures before shipment,

The product establishes a quality inspection and control mechanism according to customer needs,and through process standardization to ensure that all products meet customer quality requirements.

Quality

Shun Ji Wei has obtained the IATF-16949 Automotive Quality Management System Certification and enjoys a reputation of high quality and high reliability in the industry. The quality assurance department at Shun Ji Wei focuses on fulfilling the customer's quality requirements through sustainable management, consistency, rigorous examination, and zero defect manufacturing.

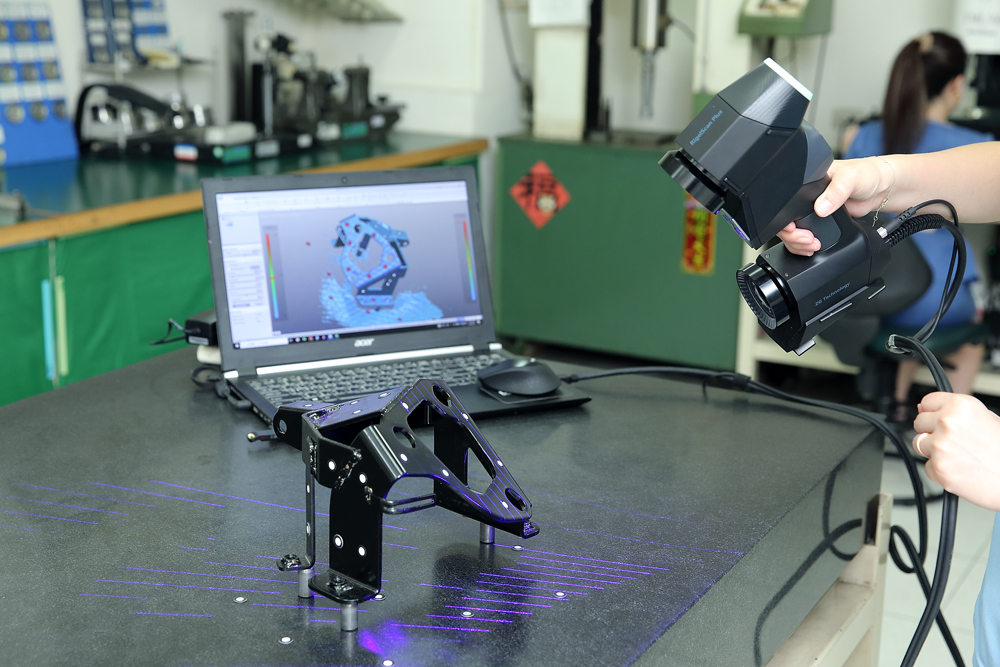

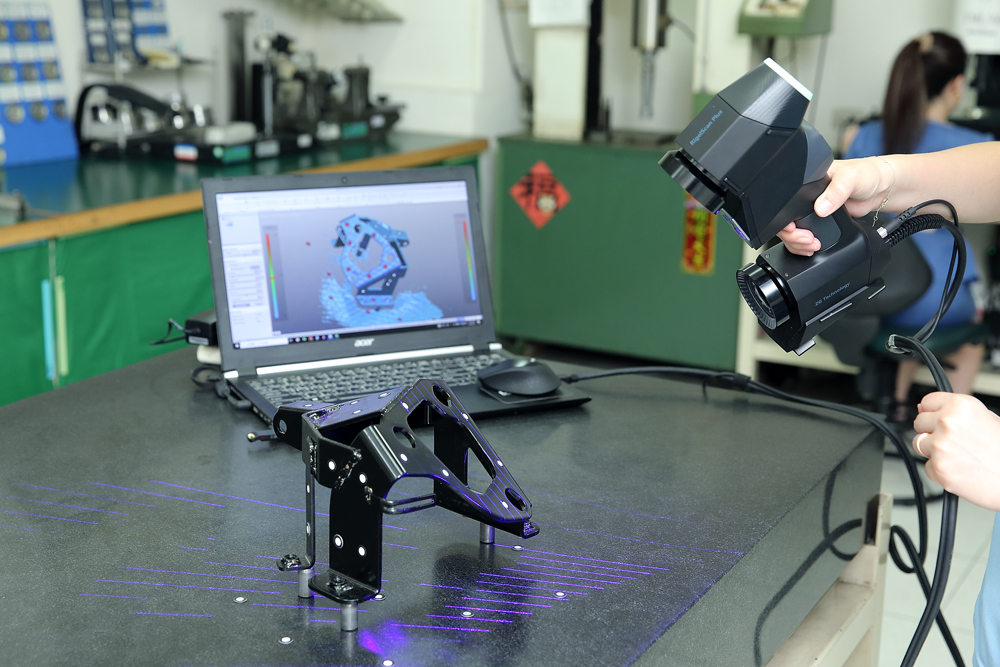

Handheld Laser 3D Scanner

The handheld laser 3D scanner adopts advanced blue light technology, which can easily achieve data acquisition on high-gloss surfaces, and can realize fine scanning of small features, with an accuracy of up to 0.02mm, and has obtained the accuracy certification of the International Measurement Center , allowing users to have a more perfect 3D scanning experience

Handheld Laser 3D Scanner

The handheld laser 3D scanner adopts advanced blue light technology, which can easily achieve data acquisition on high-gloss surfaces, and can realize fine scanning of small features, with an accuracy of up to 0.02mm, and has obtained the accuracy certification of the International Measurement Center , allowing users to have a more perfect 3D scanning experience