Stamping A cold stamping processing method uses a stamping press to punch material into the shape and size of the mold specification. Stamping can be roughly divided into several different processing types such as shearing, bending, forming and punching. Compared to forging, which is to form hot metal, stamping is usually carried out on cold metal plates. Products formed by stamping have high strength, stability, and structural integrity. It has a wide technical application range.

STAMPING

Stamping A cold stamping processing method uses a stamping press to punch material into the shape and size of the mold specification. Stamping can be roughly divided into several different processing types such as shearing, bending, forming and punching. Compared to forging, which is to form hot metal, stamping is usually carried out on cold metal plates. Products formed by stamping have high strength, stability, and structural integrity. It has a wide technical application range.

STAMPING

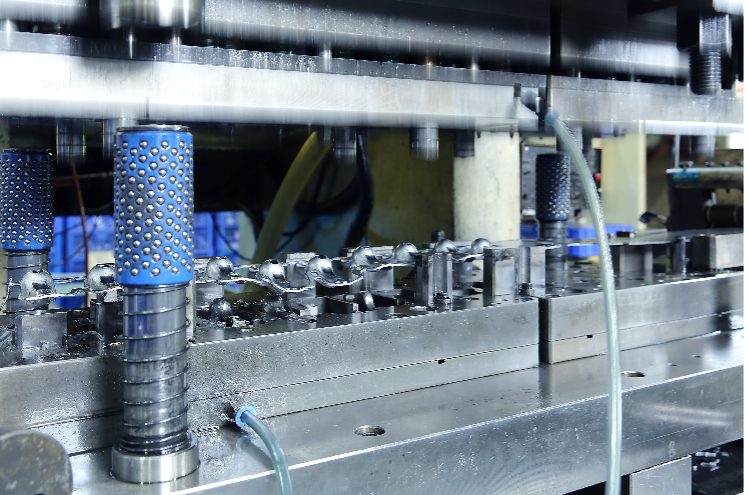

Single Punch Die

Single-punch molds are widely used, simple in structure, easy to manufacture, cheaper in mold price, but low in production efficiency. A technician will hold the metal plate on the stamping press and punch it into the shape.

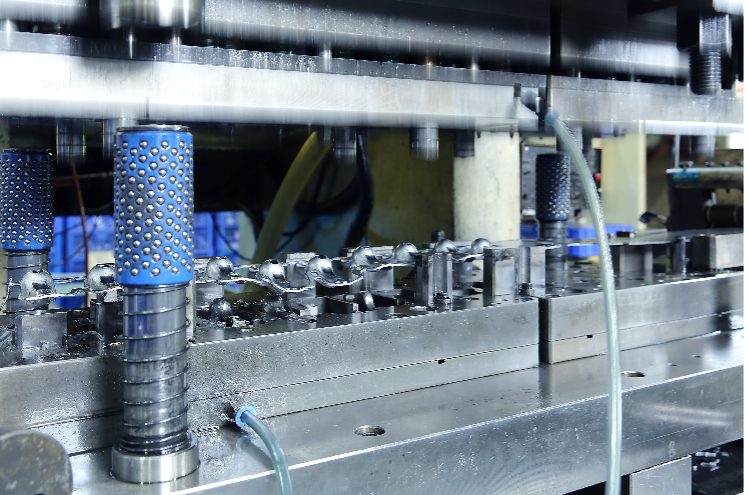

Progressive Die

Progressive forming has the advantage of completing multiple mold stages on one punching machine. However, the complexity of the mold design is relatively high so costs are increased.

Single Punch Die

Single-punch molds are widely used, simple in structure, easy to manufacture, cheaper in mold price, but low in production efficiency. A technician will hold the metal plate on the stamping press and punch it into the shape.

Progressive Die

Progressive forming has the advantage of completing multiple mold stages on one punching machine. However, the complexity of the mold design is relatively high so costs are increased.

Welding combines two or more metal materials into one by means of pressure or heat. Shun Ji Wei mainly uses CO2, oxyfuel welding, and spot welding technology.

WELDING

Welding combines two or more metal materials into one by means of pressure or heat. Shun Ji Wei mainly uses CO2, oxyfuel welding, and spot welding technology.

WELDING

Automated Welding Robot

A welding robot is reprogrammable and allows for automatic processes. It can repeat the most efficient welding procedure, which produces consistent quality, lowers production costs, and increases productivity.

Spot Welding

Spot welding uses a high electric current to weld a solder joint and combine the two workpieces. It’s suitable for automotive bodies and parts, but it cannot weld parts with sealing requirements.

Bent Pipe Bending increases functionality after production. Bent pipes have a long service life and a wide range of applications.General advantages include good flexibility, high pressure resistance, and low obstruction.General advantages include good flexibility, high pressure resistance, and low obstruction.

BENT PIPE

Bent Pipe Bending increases functionality after production. Bent pipes have a long service life and a wide range of applications.General advantages include good flexibility, high pressure resistance, and low obstruction.The elbows generally have the advantages of good flexibility, high pressure resistance, and low resistance.

BENT PIPE

Straight

Bent Pipe

Straight